Why CSI Is an Industry Leader

Throughout its nearly 100-year history, CSI has consistently proved itself to be an innovative leader in the caps and closures space. CSI’s long track record combines with its widespread geographic footprint, client roster of major brands, and broad product portfolio to set it apart from other closure manufacturers. Here’s what you need to know about what makes CSI an industry leader:

Long History of Excellence

The business was originally started under the name Alcoa in the 1930s as an aluminum closure manufacturer. One of the first major customers was H.J. Heinz, which used the popular Goldy closure to seal sauces and ketchup bottles. Alcoa continued to develop and produce aluminum closures for the next 50 years, and in the 1970s, the business unified its worldwide metal closure and capping equipment businesses under the name Alcoa Closure Systems International (Alcoa CSI).

In the 1980s, Alcoa CSI acquired H-C Industries, Inc., which had developed a patented compression molding process to make plastic closures for carbonated soft drinks. This acquisition helped Alcoa CSI expand into plastic closures in addition to aluminum closures. In the 1990s, Alcoa CSI launched the landmark Double-Lok closure, which helped cement the company’s position as one of the most prominent beverage cap manufacturers. Significant international expansion also took place from the 1990s into the 2000s, with plants, offices, and headquarters opening up throughout North America, South America, Europe and Asia.

In 2008, Rank Capital Management acquired Alcoa’s Packaging Group, including Alcoa CSI. As part of the acquisition, the Alcoa name was dropped and the company became known simply as Closure Systems International (CSI). In 2019, the North American and Japanese businesses of CSI were acquired by Cerberus Capital Management.

Strategic Locations

Today, CSI is headquartered in Indianapolis, IN, and produces 50+ billion closures annually across its 9 manufacturing sites. CSI has manufacturing plants in the North America, Central America and Asia; this widespread geographic reach helps it remain an industry leader. Multiple plants mean shorter transport times for caps and closures since they are not all coming from one location. It also reduces wait times for customers, since closures are spread across multiple plants instead of being bottlenecked at a single location. Maintaining so many plants in multiple countries also means that CSI has hands-on experience and understanding of many regional markets.

Major Brands and Clients

CSI has worked with nearly every significant beverage brand around the globe and has long-standing relationships with many of them. For instance, CSI partnered with Coca-Cola to launch a new closure for the Dasani water bottle that utilized 30% post-consumer recycled content. The closure won the 2020 Caps & Closures Innovation Award at the Plastics News’ Plastics Caps & Closures annual conference. CSI is also partnered with several major sustainability organizations — including the US Plastic Pact, Sustainable Packaging Coalition, and the Association of Plastic Recyclers — to support clients’ environmental goals.

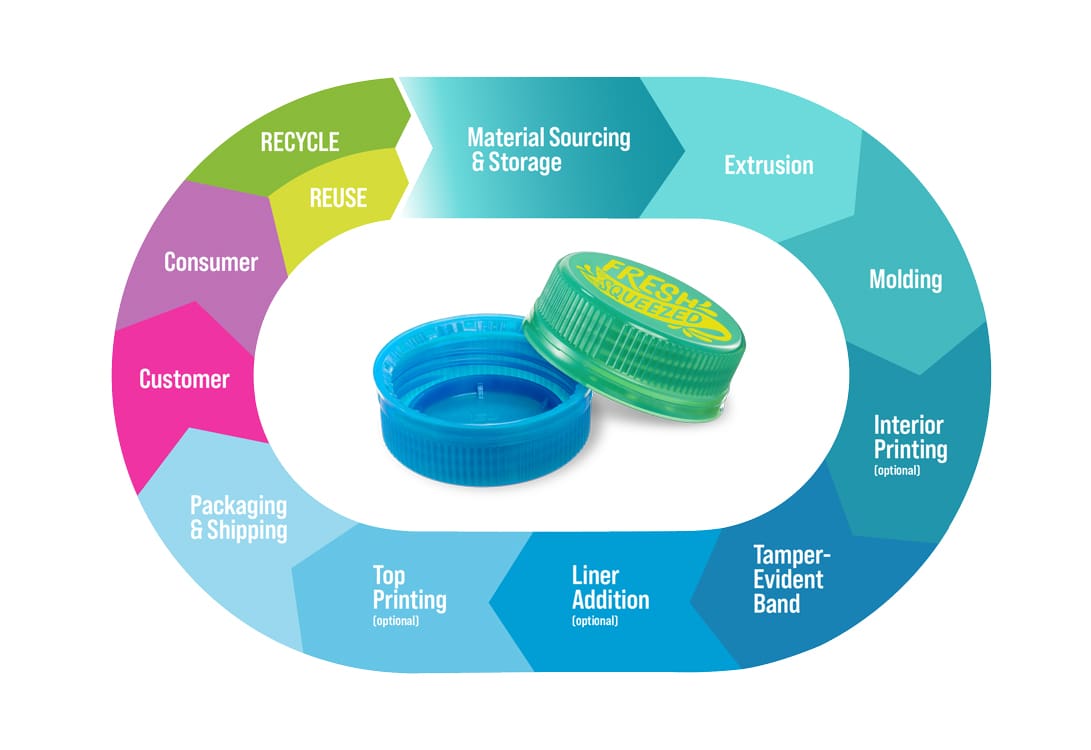

Broad Product Portfolio

CSI offers more than 90 stock closures to choose from across a wide variety of market segments, including food and beverage, automotive, and pharmaceuticals. Closure diameters range from 18mm to 100mm, fitting everything from single-serve liquor bottles to large peanut butter jars. CSI’s closures are also compatible with multiple bottle and package types, bottle finishes, and application/fill processes to suit a wide variety of uses. CSI’s closures can be manufactured with PolyCycle PCR material. To browse CSI’s vast stock closure portfolio, visit the Capfinder page.

PolyCycle recycled post-consumer content is now available commercially for all of CSI’s stock closures, which can be made with up to 100% PCR content. For more information, see the PolyCycle press release. CSI also designs and engineers completely custom closures to fit niche applications. Contact the team today to get a quote started if you’d like to collaborate with an industry leader in the cap and closures space.

- How long has CSI been in business?

- Nearly 100 years. Originally founded in the 1930s as an aluminum closure manufacturer for companies like H.J. Heinz.

- How has CSI grown over the years?

- Expanded into plastic closures in the 1980s and grew internationally throughout the 1990s and 2000s.

- Launched innovative closures like the Double-Lok and achieved significant market share in beverage caps.

- Where is CSI headquartered?

- Indianapolis, IN, USA.

- What makes CSI an industry leader?

- Innovative and in-depth product portfolio.

- Product portfolio designs compatible with PolyCycle PCR resin.

- Long-term working relationships with the Who’s Who of the food and beverage markets.

- Shorter transport times for customers due to geographically spread locations.

- Reduced wait times for closures due to production across multiple plants.

- Hands-on experience and understanding of diverse regional markets.

- What kind of clients does CSI work with?

- Major beverage brands around the world, including Coca-Cola.

- How does CSI demonstrate its commitment to sustainability?

- Partners with sustainability organizations like the US Plastic Pact.

- Offers stock closures with up to 100% post-consumer recycled content (PolyCycle).

- What kind of variety does CSI offer in closures?

- Over 90 stock closures across various markets (food & beverage, automotive, pharmaceutical).

- Closure sizes range from 18mm to 100mm, fitting various containers.

- Compatible with multiple bottle/package types, finishes, and filling processes.

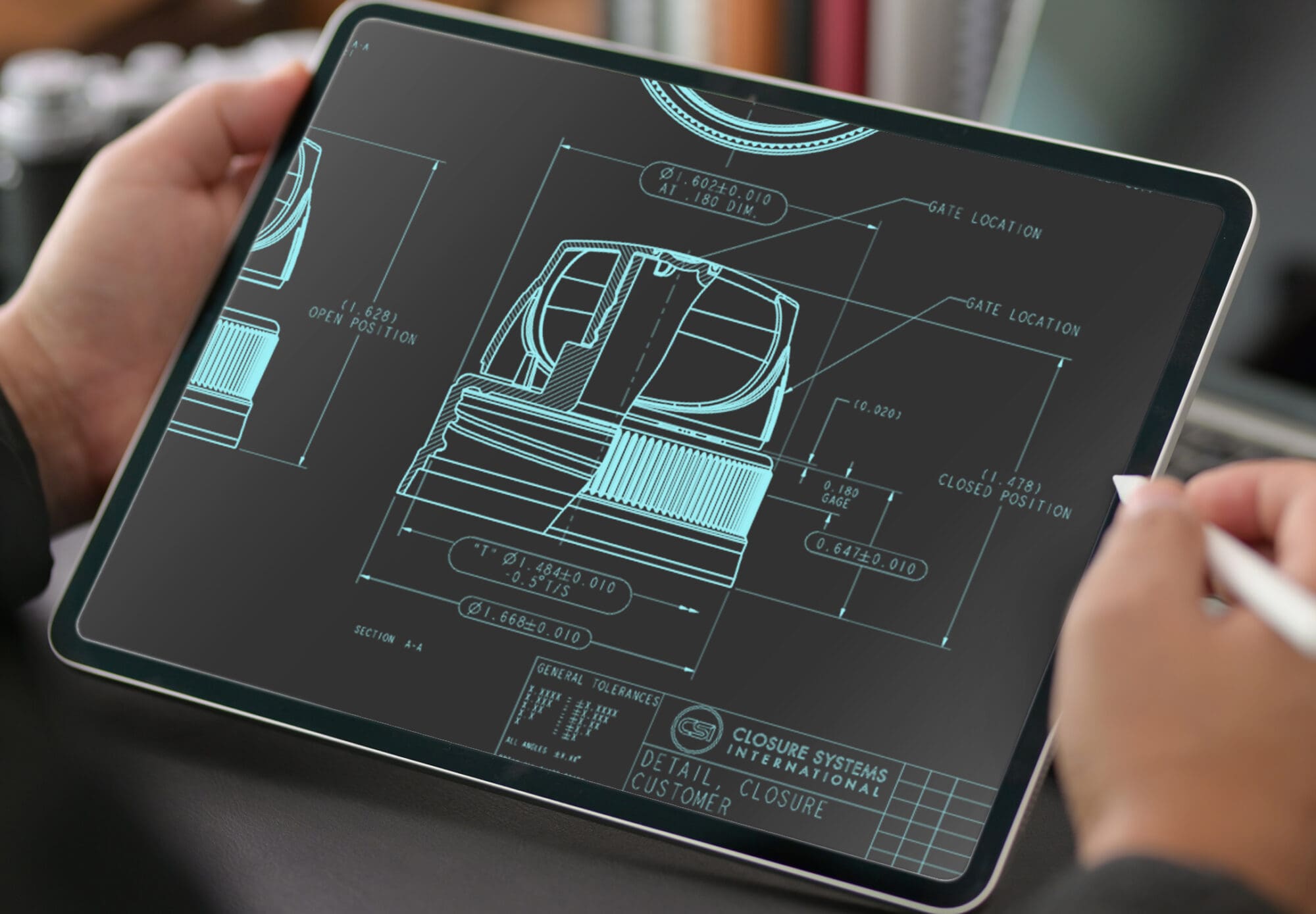

- Can CSI create custom closures?

- Yes, CSI offers custom closure design and engineering for specific needs.

Recent Comments