The global consumer packaged goods (CPG) industry, especially in the food and beverage sector, is undergoing a remarkable shift. Sustainability has taken center stage, and it’s a topic that resonates deeply with today’s consumers. In this post, we’ll dive into the benefits of sustainable closures from a CPG perspective and explore the world of Post Consumer Recycled (PCR) resin closures.

The Importance of Sustainable Closures

Traditional closures, often made from virgin plastics, have long been a staple in the packaging industry since the 1950s. However, their environmental impact has come under increasing legislative and consumer scrutiny recently. Consumers today are increasingly concerned about the environmental footprint of the products — and packaging — when they make purchases. On the industry side, CPG companies are proactively working to meet consumer demand and aspire toward fulfilling their broader sustainability goals. In light of these shifts, let’s consider how sustainable closures can play a pivotal role in reducing the carbon footprint of packaging, preserving natural resources, and building brand reputation.

Benefits of Sustainable Closures

- Reduction in Carbon Footprint: Sustainable closures, particularly those made from PCR resin, make a remarkable dent in carbon emissions. PCR resin closures require 79% less energy to manufacture and emit fewer than 67% greenhouse gases. Plus, since they use recycled materials, they curb the demand for virgin plastics, further reducing the carbon footprint linked to the processing of new materials.

- Preservation of Natural Resources: Embracing sustainable closures conserves natural resources. By choosing PCR resin closures, CPG companies help decrease the need for new plastics — a giant step toward creating a more circular economy where materials are reused and recycled, rather than ending up as waste.

- Enhanced Brand Reputation: CPG companies that prioritize sustainable closures gain a competitive edge in the marketplace. They’re meeting consumer expectations and attracting a growing number of eco-conscious shoppers. Sustainable packaging signals a commitment to responsible business practices and can bolster a brand’s reputation.

Post Consumer Recycled (PCR) Resin Closures

PCR resin closures are a shining example of sustainable packaging solutions. These closures are crafted from recycled plastic materials sourced from post-consumer waste. Their advantages are clear:

Decreased Dependence on Virgin Plastics:

PCR resin closures reduce our reliance on virgin plastics, diverting plastic waste away from landfills and incineration facilities. By using recycled materials, eco-conscious companies contribute to the reduction of pollution and the conservation of fossil fuels.

Closing the Recycling Loop:

PCR resin closures complete the recycling loop. They give a fresh purpose to plastics that might otherwise become waste, showcasing the potential of a circular economy. This concept aligns with broader sustainability goals and promotes responsible resource management.

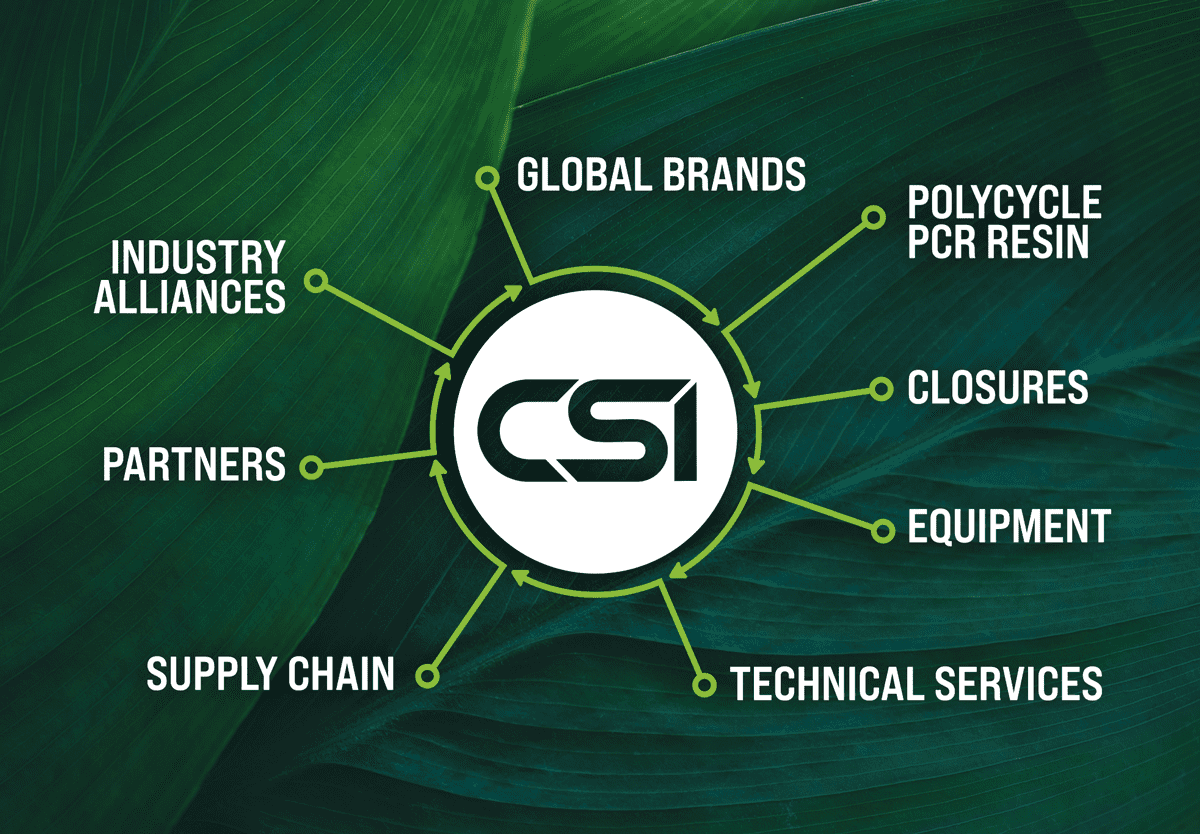

PolyCycle® PCR Resin Closure Systems International Group is leading the industry in the transition to sustainable closure materials.

- PolyCycle® PCR resin materials feature proprietary Closure-to-Closure technology made of 100% PCR content that is also 100% recyclable.

- CSI’s innovative sustainable material sourcing and cleaning practices create closures that not only meet industry performance standards but also surpass environmental expectations.

- PolyCycle® resin closures offer all the advantages of PCR with the added assurance of quality and reliability. CPG companies can confidently adopt PolyCycle® PCR resin closures, knowing that they’re contributing to a more sustainable future while upholding the integrity of their products.

See how caps produced with PolyCycle® resin deliver a true closed-loop packaging solution specifically for food and beverage closure applications. Watch Video

A Future Outlook

While sustainable closures hold immense promise, the ahead challenges are real. Cost, supply chain complexities, and regulatory hurdles can slow the widespread adoption of sustainable closures. Collaboration across the CPG industry, technological advancements, and supportive policies will positively address these challenges and drive broader adoption. In conclusion, the future of sustainable packaging and closures looks promising. Both are more than just a trend; they’re a necessity for the CPG food and beverage packaging industry. As technology evolves and consumer demand continues to rise, we can expect to see even more innovative and sustainable solutions emerge in the packaging industry.

Next Steps

Closures made with PolyCycle® PCR resin represent responsible innovation at its best. They offer a practical and impactful way to make packaging more sustainable. Reach out to the CSI team here if you’d like to inquire about PolyCycle® PCR resin, or partnering with us to help achieve your sustainability aspirations.

Recent Comments