In the competitive world of beverage packaging, the importance of a well-designed and functional bottle cap cannot be overstated. As consumer preferences evolve and sustainability gains momentum, businesses are seeking ways to differentiate themselves through customized packaging solutions. Developing an expertly engineered custom bottle cap with an experienced plastic closure manufacturing company can offer a myriad of benefits that go beyond the surface.

In this post, we will explore the advantages of investing in custom plastic bottle caps and how partnering with industry leaders can drive innovation in your packaging strategy.

- Tailored Solutions for Brand Identity:

A custom plastic bottle cap allows brands to showcase their unique identity and distinguish themselves in a crowded market. Whether it’s a distinct color, shape, or branding elements like embossing or top printing, customization enables companies to create a memorable and recognizable packaging solution. According to Packaging Strategies, custom packaging plays a crucial role in establishing brand loyalty, and a distinctive bottle cap is a tangible expression of your brand’s commitment to quality and innovation.

- Enhanced Functionality and Customer Experience:

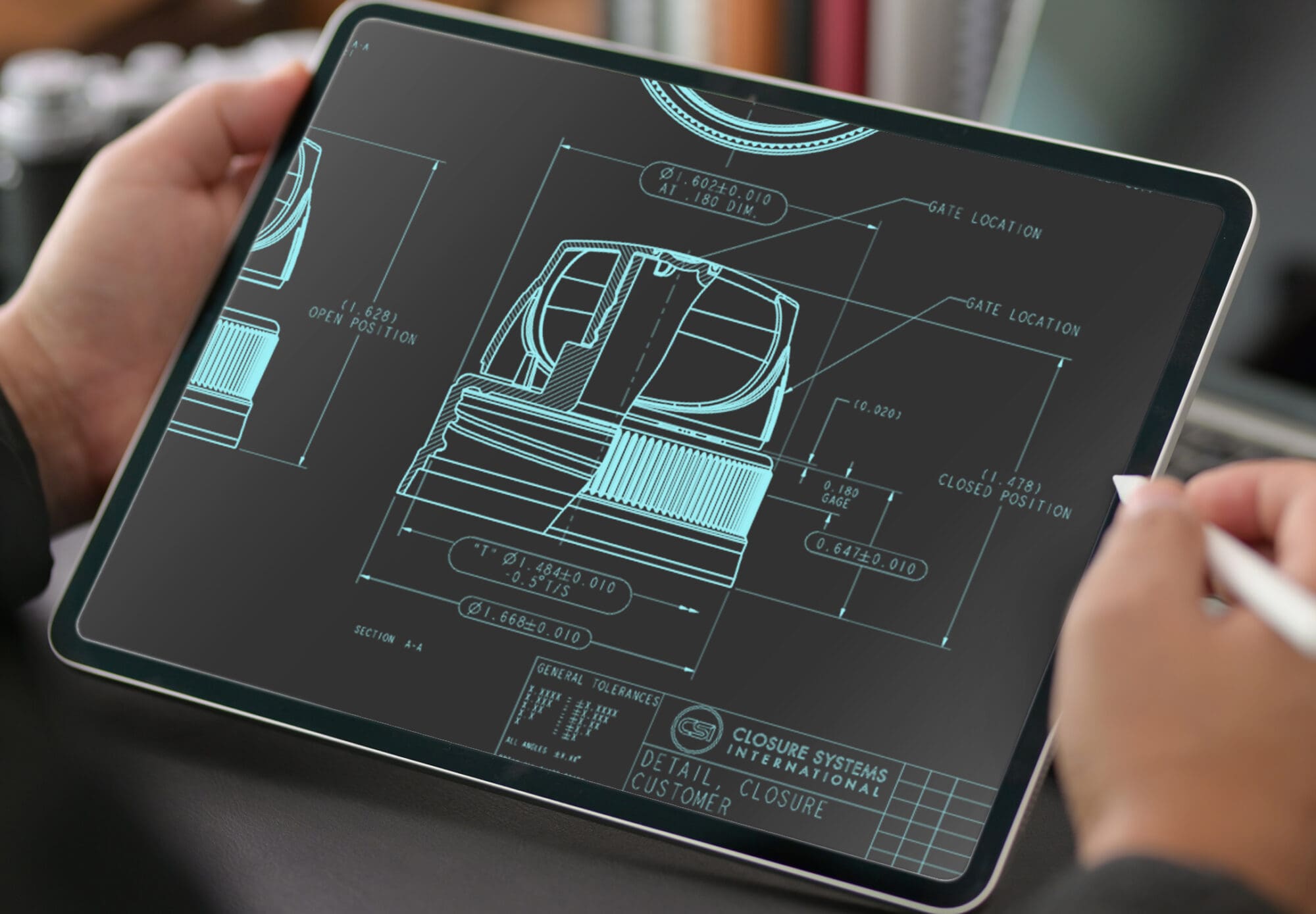

Working with experienced plastic closure manufacturing companies ensures that the custom bottle caps not only look good but also function seamlessly and safely. CSI emphasizes the importance of designing closures that align with the beverage brand characteristics and ensure optimal freshness and prevent leakage. Customization allows for precision in fit, for a perfect seal that preserves the product’s integrity and enhances the overall customer experience. CSI offers closures in sixteen diameters from 18mm to 110mm for more than 65 bottle finishes.

- Innovative Materials for Sustainability:

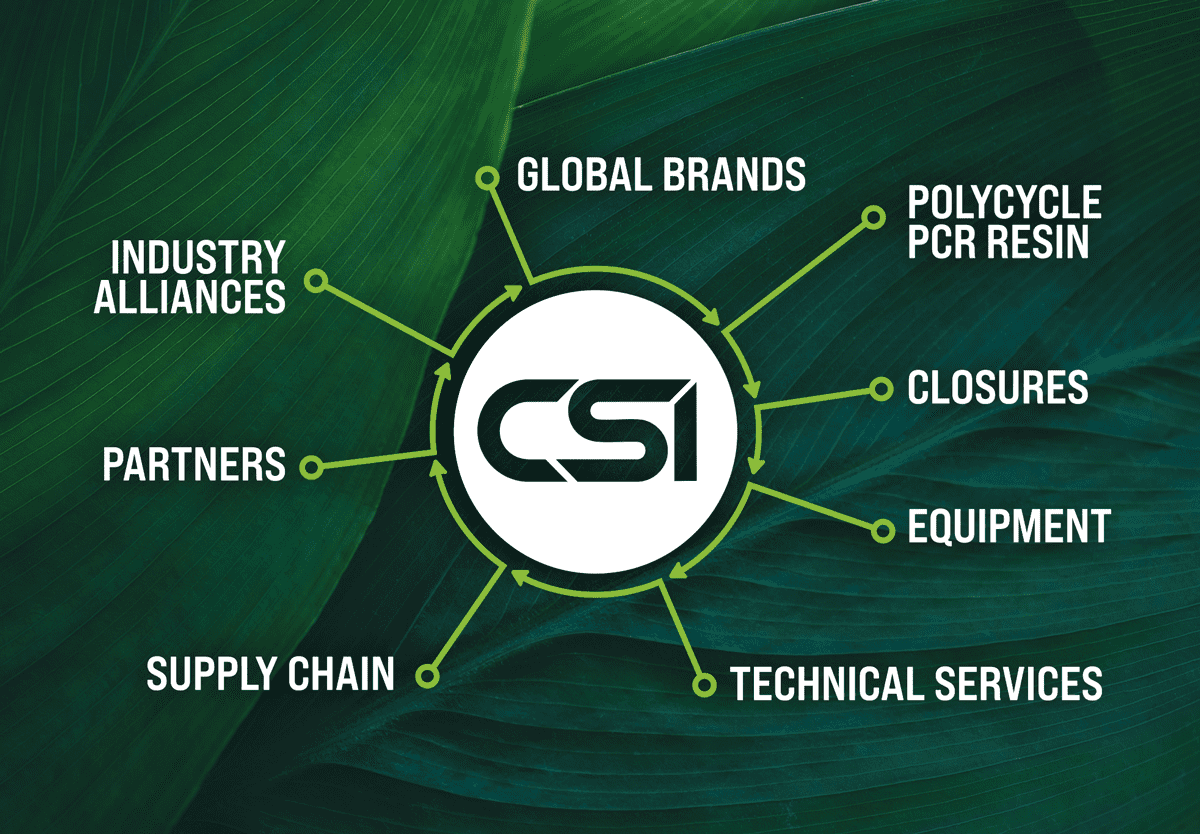

The push towards sustainability is a defining trend in the packaging industry. To address environmental concerns, businesses are increasingly turning to recyclable and sustainable materials for their packaging solutions. By collaborating with expert manufacturers, brands can explore innovative materials that align with their sustainability goals. BevNet reports a rising interest in eco-friendly packaging and a custom plastic bottle cap made from recyclable and Post Consumer Recycled (PCR) materials which can significantly contribute to reducing the environmental impact. With their development of PolyCycle® recycled (PCR) resin, CSI is a recognized leader in manufacturing bottle caps that meet the growing demands for sustainability, performance, and price.

- Meeting Regulatory Compliance:

Navigating the complex landscape of regulatory requirements is a challenge for beverage manufacturers. Compliance with safety and quality standards, as outlined in Packaging Digest, is critical to building trust with consumers and avoiding potential legal issues. Working with an experienced plastic closure manufacturing company can help beverage brands get ahead of legislation demands, as well as back up their sustainability claims with confidence. This safeguards custom bottle caps to meet industry standards and comply with regulations.

- Cost Efficiency and Scalability:

Contrary to common misconceptions, investing in custom plastic bottle caps can be a cost-effective solution in the long run. Expert manufacturers understand the intricacies of production processes, enabling them to optimize costs while maintaining high-quality standards. Additionally, custom bottle caps can be designed with scalability in mind, accommodating future growth without compromising efficiency or cost-effectiveness.

- Market Differentiation and Consumer Appeal:

In a market flooded with choices, standing out is essential for attracting and retaining consumers. A unique and well-designed custom bottle cap can be a powerful marketing tool, creating visual appeal and generating interest among consumers. Beverage Digest emphasizes the importance of packaging as a key influencer of consumer purchasing decisions, and a custom bottle cap can be a game-changer in setting your brand apart from the competition.

Custom closures offer numerous benefits for beverage brands to innovate tailored solutions, enhance functionality, ensure regulatory compliance, and improve packaging sustainability. Developing custom plastic bottle caps with experienced manufacturers enables businesses to navigate industry trends, positively impacting their brand while appealing to eco-conscious consumers.

Want to learn more about working with CSI’s innovation team on a custom closure solution? Reach out to our customer service experts at +1 (317) 390-5000, or contact us here.

Recent Comments