Reliable, attractive beverage packaging and closures are essential for maximum customer satisfaction. By catching a consumer’s eye and preserving the integrity of the product, beverage closures contribute to a positive brand image and increase consumer goodwill and loyalty. Partnering with an industry leader like Closure Systems International (CSI) can help you achieve operational excellence in closure manufacturing without an in-house team.

How bottle packaging and capping impacts customer satisfaction

When it comes to beverages, bottle packaging is key to customer satisfaction. First of all, when browsing in the store for a new beverage, the packaging will be the very first thing the consumer sees. This means that packaging is essential for creating a cohesive brand appearance and catching consumers’ attention by standing out from competitors.

Packaging is also crucial for maintaining the integrity of the product itself. If the cap or bottle fails the product may leak or spoil, which will adversely impact customer satisfaction. Bottled beverages are a competitive space and consumers have many options to choose from: One bad experience due to packaging can make a consumer switch to another brand. On the flip side, high quality packaging will encourage consumers to make repeat buys, creating customer loyalty and contributing to the business’ bottom line.

Finally, sustainable and recyclable packaging also aligns with the values of eco-conscious consumers — and will help your brand further stand out among the competition. Many eco-friendly consumers will opt for a brand that provides eco-friendly packaging over one that does not, further contributing to customer satisfaction.

How CSI operational excellence supports customer satisfaction

In order to promote customer satisfaction, you need well-designed beverage packaging and capping equipment to go along with it. Partnering with an industry leader such as Closure Systems International (CSI) can help your company improve its packaging designs and production line efficiently all at once, while also raising customer satisfaction scores.

CSI works with some of the biggest beverage brands around the world to help them create eye-catching yet reliable closures that consumers purchase time and again. CSI produces 50+ billion closures annually across its multiple manufacturing sites, a high production volume that is made possible through its operational excellence. Go to the beverage aisle in any gas station or supermarket, and many of the closures that you see will have been produced at a CSI manufacturing site.

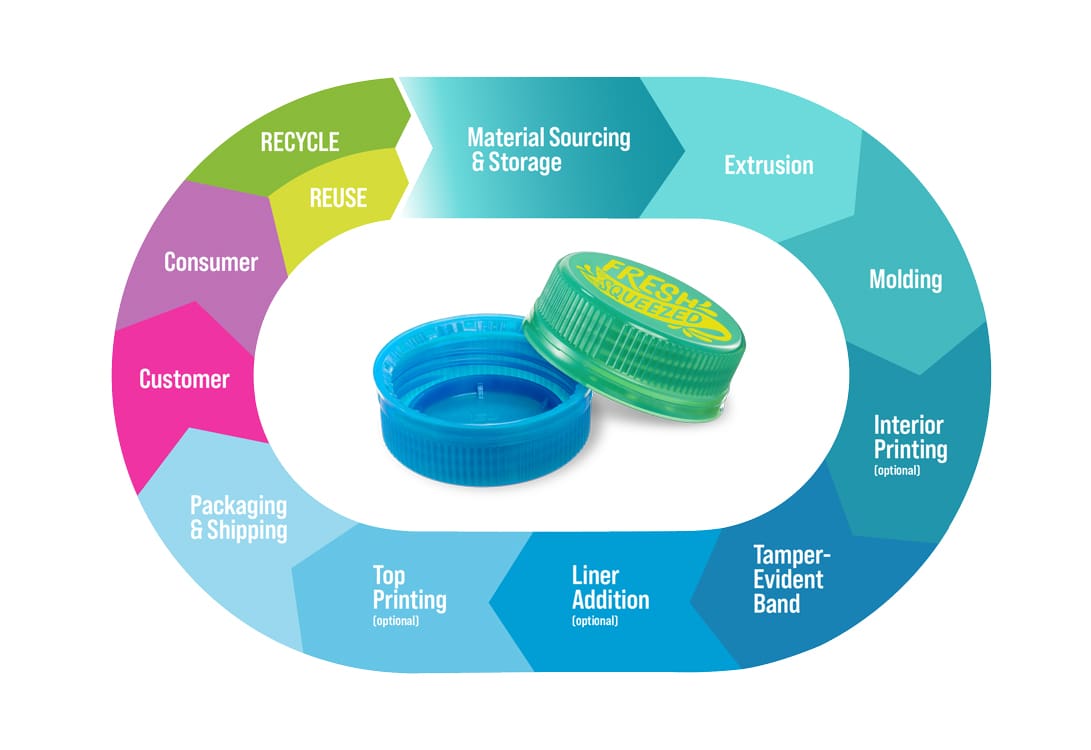

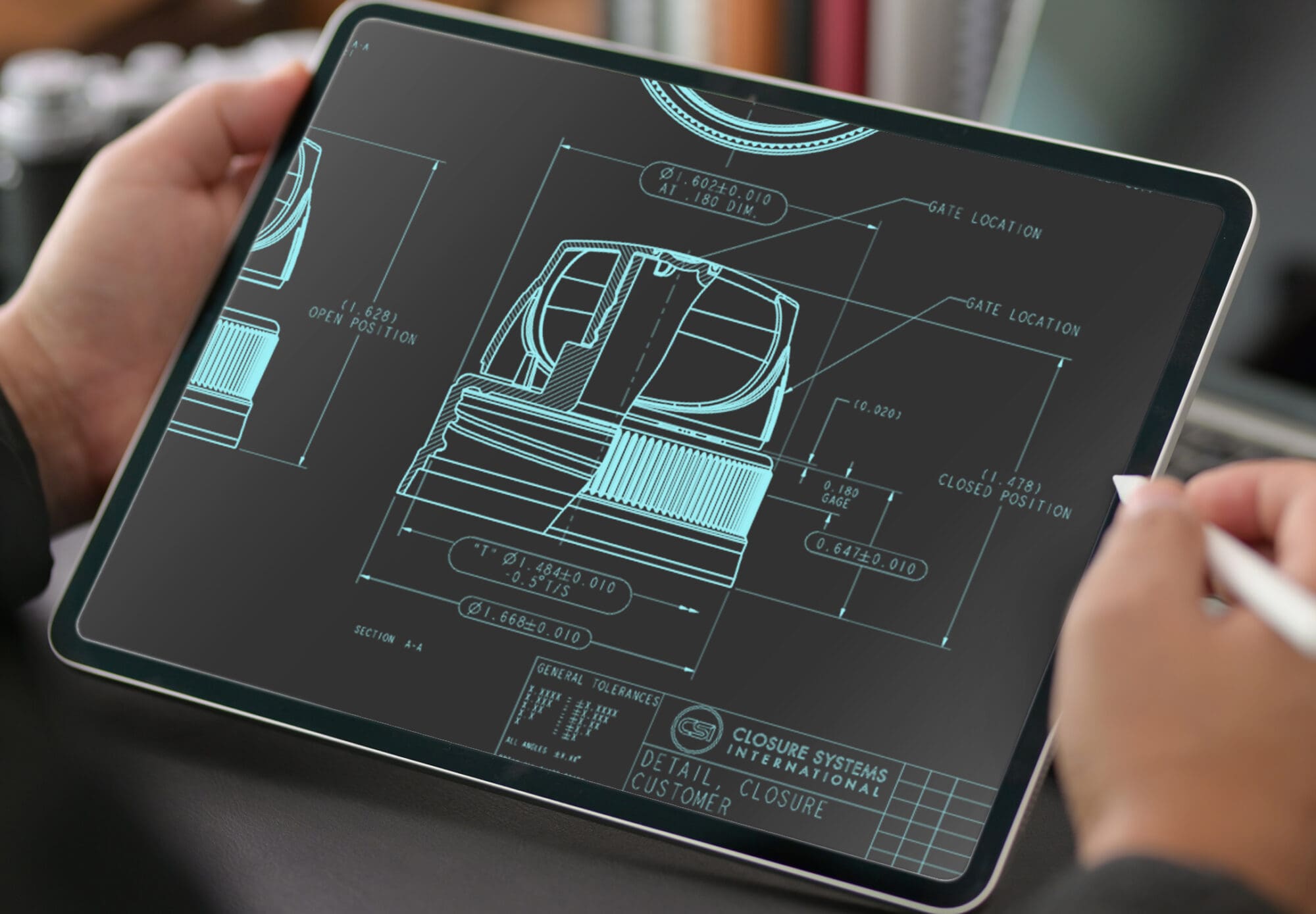

CSI makes standard closures for all major beverage categories, including carbonated soft drinks, bottled water, juices, isotonics, teas, adult beverages, and dairy. We also offer the option to design custom closures to any specifications and requirements. We also manufacture closures for non-beverage applications such as food, pharmaceutical and automotive fluids, providing a truly diverse product portfolio to match our operational excellence. At CSI, we also build and service our own capping machines in addition to offering a spare parts program to help prolong the life cycle of equipment.

Looking to increase customer satisfaction by joining forces with a veteran packaging partner like CSI? Contact CSI today at 1-800-311-2740 or csifeedback@csiclosures.com to discuss which of our standard beverage closures would work best for your products, or to get a quote for a custom closure.

Recent Comments