When it comes to reliable closure application and efficient production performance, Closure Systems International (CSI) sets the global standard. From precision capping machines to robust cap handling systems and quick-turnaround spare parts, CSI supports demanding operations across the beverage, food, household, and industrial packaging sectors.

Backed by decades of industry expertise, CSI’s capping equipment portfolio is built for speed, uptime, torque accuracy, closure integrity, and long-term performance. This operational excellence is made possible through four key areas of equipment innovation: advanced capping machines, efficient cap handling systems, precision headsets and chucks, and a responsive spare parts program.

High-Performance Capping Machines

CSI’s capping machines handle high throughput in demanding product requirements, supporting nearly every type of closure and bottle configuration. Designed for modularity and easy integration, these systems meet the evolving demands of modern bottling lines.

Series W138 Capper

A compact, single-head capper with quick changeovers, designed for lower-volume runs with multiple container types. Manually operated machine perfect for lab settings, pilot lines, or specialty packaging.

Markets: Pilot lines, specialty co-packers

Series 200 Capper

Dual-capability machine that handles both aluminum roll-on and plastic closures. Offers operational flexibility for contract packagers and diversified filling lines.

Markets: Adult Beverages, Dairy Fresh Milk, Food, Pharmaceutical, Industrial Chemicals, Household Chemicals

Series 200E Capper

High-speed, low-maintenance system optimized for large-volume operations. Known for consistent torque delivery and simplified service access.

Markets: Carbonated Soft Drinks, Bottled Water

Series 900T Capper

Designed for high-speed bottling environments, this model features mechanical torque control and continuous motion to boost output while maintaining precision.

Markets: Non-Carbonated Beverages, Dairy (Extended Shelf Life), Food (Premium)

Series 5000 Capper

Medium-speed capper designed for specialized capping applications. Specialize in Alumitek, ROPP and combination machines for both aluminum roll on and plastic closure application.

Markets: Carbonated Soft Drinks, Adult Beverages, Non-Carbonated Beverages

These machines are offered in turret or freestanding formats, built from corrosion-resistant materials for durability in wet-fill or aseptic environments. CSI’s high-speed systems can be configured with 4 to 39 heads and operate at up to 3,000 bottles per hour per head.

Integrated Cap Handling Systems

Efficient closure handling plays a critical role in a smooth capping process. CSI’s cap handling solutions deliver continuous, controlled feeding to minimize jams and keep production running at full speed.

- Built for fast changeovers to reduce downtime

- Customizable to handle multiple closure types

- Engineered for easy maintenance and operator safety

These systems simplify line configuration and maintain steady cap flow across varying production requirements. CSI offers elevator sorters as well as rotary sorters to meet your production line needs. For more information on our elevator and rotary sorters, click on the links below:

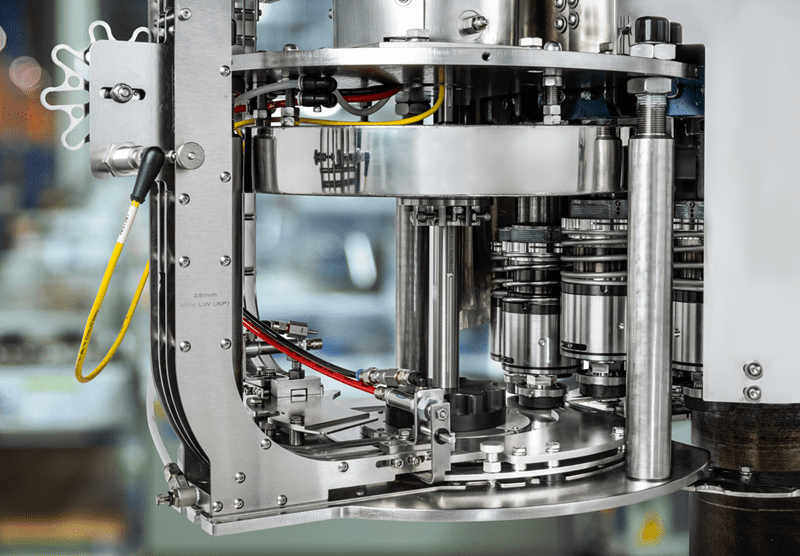

Precision Headsets & Chucks

For consistent torque and closure integrity, CSI supplies a full range of OEM headsets and chucks that integrate seamlessly with its capping machines. Each component is engineered to meet specific closure and container requirements, ensuring application reliability and repeatability over time.

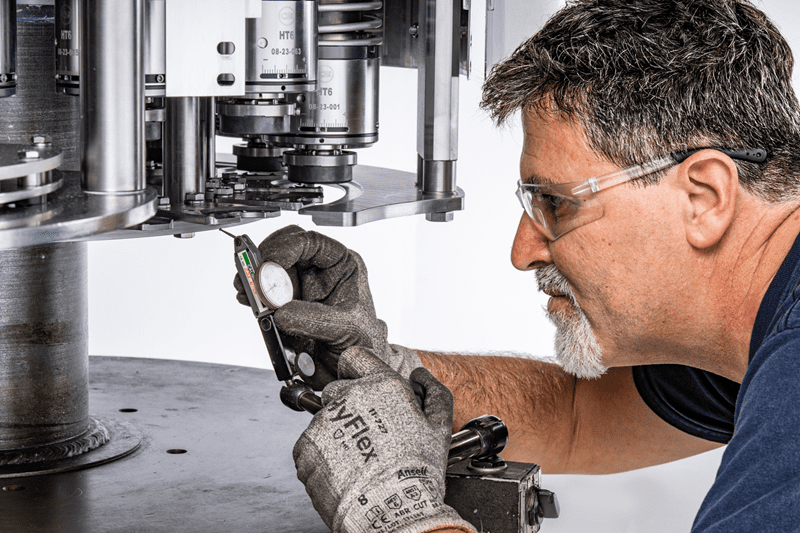

PM Select Program

Downtime is costly. CSI’s PM Select program supports proactive maintenance with fast delivery and knowledgeable support. With key replacement parts held in stock and short lead times on most orders, smaller customers and global brands alike can count on:

- Improved line efficiency and reduced stoppages

- Lower maintenance costs and simplified repairs

- Enhanced quality and fewer packaging defects

CSI’s Field Service and Technical Specialists support spare parts and can assist with capper audits, rebuilds, headset and spindle exchanges, troubleshooting, etc.

Built for Performance. Backed by CSI.

Whether you’re launching a new line or optimizing an existing one, CSI’s equipment delivers more than machinery—it brings performance consistency and long-term value to every operation.

To learn more or view the complete equipment portfolio, visit CSI’s Equipment & Services page.

Explore CSI’s technical services and support programs for expert support that keeps high-volume capping operations performing at their peak.

Recent Comments