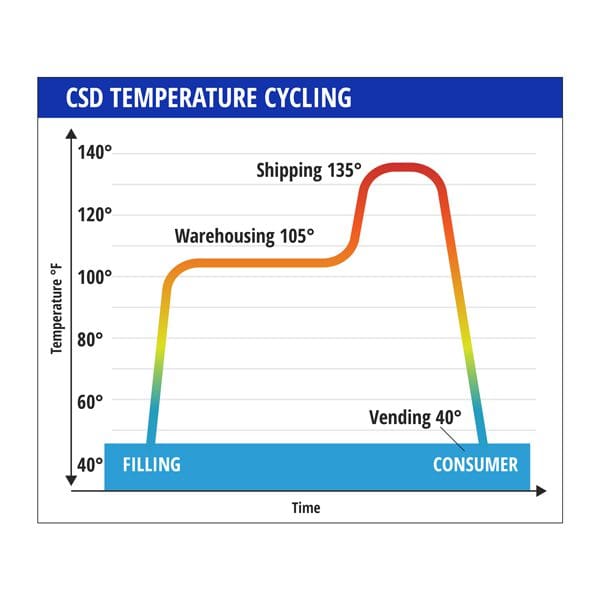

CSI research shows that filled PET bottles can be subjected to extreme “temperature cycling” – from less than 5˚ C to over 50˚ C. These conditions can cause shrinkage of the heat-sensitive PET material, which can cause a gap to develop between the bottle finish and the closure. The result is loss of CO2 and product freshness.

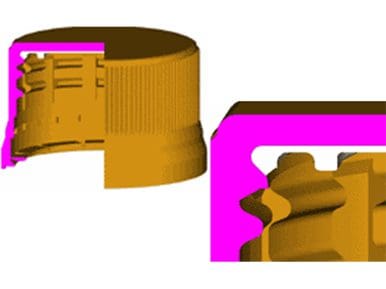

Innovative Euro-Lok HR liner maximizes seal integrity and product freshness, even at temperatures as high as 50˚ C, using a plug-side-seal and top seal design.

Euro-Lok HR’s inner liner profile compensates for neck shrinkage in PET bottles by remaining in continual contact with the bottle finish, preventing CO2 from escaping.

Euro-Lok HR improves the mechanical seal and maximizes product freshness in conditions where extreme temperatures can cause package leakers throughout the distribution channel. CSI’s proven application performance and capping equipment provides bottlers with the best sealing performance in the industry under extreme temperature cycling conditions.

- Extensive range of shell colors to attract customers

- Precise multi-color top printing for clear communication

- Easy to recycle – environmentally friendly

- Industry-leading application performance

- Designed for Pick and Place and Direct Pick-Up application

- Interchangeable with Euro-Lok set-up